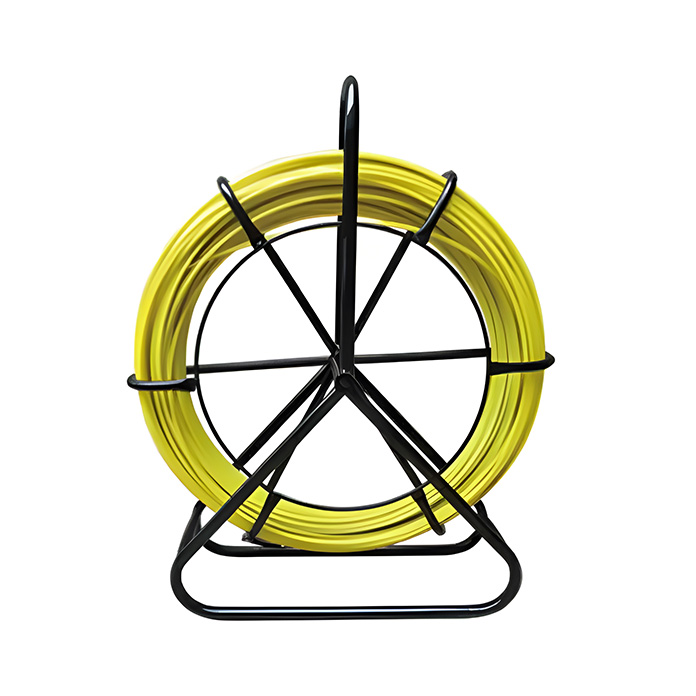

6mm duct rod mini duct rodder

Description: The 6mm micro duct rodder is a specialized tool designed for installing fiber optic or micro-cables through small-diameter (typically 5-10mm) ducts or conduits. It is a key solution for modern, high-density FTTH (Fiber to the Home) and last...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

The 6mm micro duct rodder is a specialized tool designed for installing fiber optic or micro-cables through small-diameter (typically 5-10mm) ducts or conduits. It is a key solution for modern, high-density FTTH (Fiber to the Home) and last-mile network deployments.

Typical Components & Operation:

Rod Material: Usually a flexible yet strong glass fiber reinforced plastic (GFRP) rod, offering a good balance of pushability and bend resistance.

Diameter: The core rod is 6mm, making it compatible with mini/micro ducts.

Length: Available in standard coils (e.g., 100m, 200m) or on a portable drum, allowing for long, uninterrupted installations.

End Fittings: Equipped with a nose cone or coupling to easily attach a pulling rope or swivel, which is then connected to the micro-cable.

Method: It is manually pushed or fed through empty micro ducts. For longer runs or existing ducts with debris, a rodding tool or a powered feeder/rodder may be used to assist installation.

Primary Applications:

Blown Fiber Systems: Pushing through micro ducts to establish a pathway for subsequent installation of fiber bundles using compressed air (jetting/blowing).

Pre-placement of Pulling Rope: Installing a pull rope in new or existing micro ducts for future cable installation.

Direct Cable Pulling: Carefully pulling lightweight micro-cables over shorter distances.

Duct Blockage Clearing: Sometimes used to clear minor obstructions in small ducts.

Key Advantages:

Accessibility: Enables installation in narrow, space-restricted pathways common in modern building entry points, underground microduct networks, and in-building risers.

Efficiency: Facilitates faster and less invasive installations compared to traditional methods for small cables.

Future-Proofing: Essential for creating scalable fiber infrastructure where multiple micro ducts are installed in advance, and fibers are blown in on demand.

Important Considerations:

Duct Condition: The duct must be clear of major obstructions and sharp bends to avoid rod damage or lock-up.

Bend Radius: Care must be taken not to exceed the minimum bend radius of the rod during handling and installation.

Pulling Tension: Adhere strictly to the manufacturer's maximum recommended pulling tension to prevent breakage.

Compatibility: Ensure the rod end fittings are compatible with the specific pulling rope, swivel, and cable grips being used.

In summary, the 6mm micro duct rodder is a fundamental, purpose-built tool for efficiently preparing pathways and installing cables within the confined spaces of contemporary telecommunications duct networks.

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01