Troubleshooting of common faults in the construction of fiberglass threading equipment

Publish Time:2026-01-23 18:24:10 Author:Xuanyao Views:93

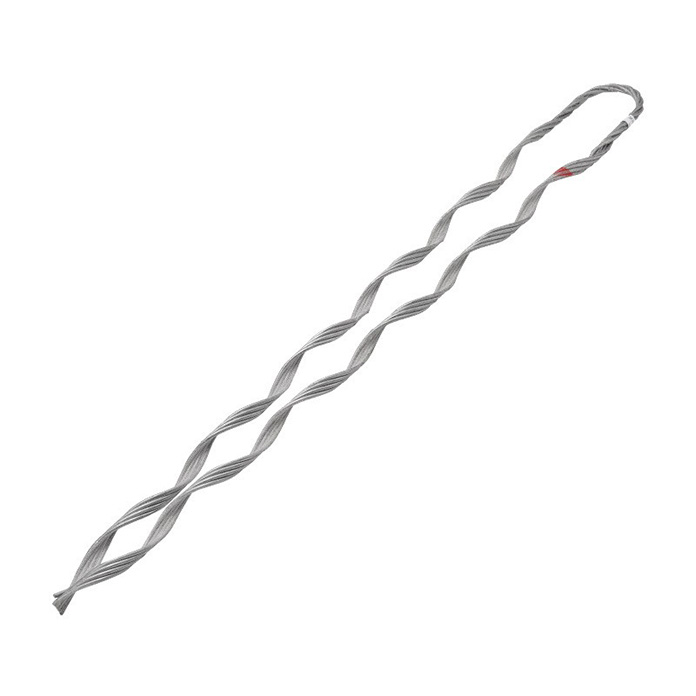

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex operating environments, equipment status, or human factors. Timely identification and troubleshooting of these faults are key to protecting wiring efficiency and ensuring the safety of the project. The following are typical faults encountered during construction and their troubleshooting strategies:

1. The threading device is obstructed or completely stuck

If the threading device suddenly cannot move forward in the pipeline, the first step is to determine whether it has encountered a physical obstacle. Possible reasons may include cement blocks, iron filings, accumulated water and sediment in the pipeline, or the presence of sharp bends and reduced diameter joints that were not constructed according to specifications. When troubleshooting, you can try gentle retraction. If the resistance is uniform, it may be due to excessive friction; If it gets stuck locally, there may be foreign objects blocking it. At this point, it is not advisable to forcefully push the pipeline. It is recommended to test it in reverse from the other end or use methods such as endoscopy or ball passing to confirm the condition of the pipeline. Open the inspection port for partial dredging when necessary.

2. The threading device slips or idles in place at bends

This phenomenon often occurs in pipelines with multiple bends or vertical upward sections, where the front end of the threading device contacts the pipe wall but cannot effectively transmit thrust. The reason is usually due to insufficient rigidity of the threading device, a small diameter, or a surface that is too smooth and lacks grip. Models with slightly larger diameters or micro textured surfaces can be replaced, and flexible guide heads can also be installed at the front end of the threading device for practical effect and passability. At the same time, using the alternating technique of "push stop micro rotation" during operation helps it gradually conform to the direction of the curve.

3. The threading device breaks or makes abnormal noises

If you hear a "pop" sound or suddenly feel lighter during construction, it is likely that a fracture has occurred. This is usually due to material aging, excessive bending, or previous impact damage. During the investigation, the task should be stopped immediately and the breakpoint position should be checked from both ends. If the severed head is left inside the tube, it needs to be salvaged by magnetic hooks, endoscopic robotic arms, or reverse threading of fine steel wires to avoid residue affecting subsequent cable threading. To prevent such problems, it is necessary to check the rod body for signs of whitening, cracking, or embrittlement before use, especially during low temperature seasons.

4. When pulling the cable, the threading device is disconnected from the cable

This malfunction is mostly caused by loose connections. Loose binding, use of regular tape, or lack of slip fasteners may all result in detachment during the pullback process. The key to troubleshooting lies in checking the connection method: high-strength zip ties, one-to-one traction heads, or double loop dead ends should be used, and protective sleeves should be installed at the end of the cable to prevent slipping. If it has been disconnected and the threading device has been retracted, it needs to be re inserted and the connection should be strengthened.

5. The threading device rebounds uncontrollably

When the threading device accumulates elastic potential energy in a curved pipeline and suddenly releases it, it may pop out at high speed and injure people. This type of malfunction often occurs when the operator is eager to retract or when there is a sudden change in the direction of the pipeline. The investigation of Enron risks should start with operational norms: always stand on the side of the operation and prohibit facing the pipe mouth directly; Maintain a constant speed when pulling back and avoid pulling forcefully; For long-distance or elastic threading devices, tension can be released in sections.

6. Surface damage leads to difficulties in subsequent cable penetration

Sometimes, although the threading device successfully passes through, the surface may have burrs or exposed fibers, which can scratch the outer layer of the cable when used again. If scratches are found on the cable sheath after construction, the status of the threading device should be traced back. Daily usage records should be established, and surface inspections should be conducted on threading devices that have experienced rough pipes or multiple pipe runs. If necessary, they should be polished or scrapped.

7. Hidden dangers of insulation failure in humid or polluted environments

In high humidity environments such as underground pipe galleries and tunnels, if conductive dust or salt adheres to the surface of the threading device, it may form a leakage channel during high-voltage threading operations. Although the fiberglass body has good insulation, surface contamination cannot be ignored. Before construction, the pole body should be cleaned, and if necessary, a megohmmeter should be used to test the surface insulation resistance to confirm compliance with Enron regulations.

Overall, the faults of fiberglass cable connectors are mainly caused by the mismatch between "human machine environment". Through standardized selection, pre use inspection, gentle operation, and post maintenance, the vast majority of faults can be prevented or disposed of at an appropriate speed. The key is to establish the awareness that 'tools are the key to safety', rather than just seeing them as auxiliary consumables.

Related News

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex op...

-

Common usage issues of fiberglass threading device

Although fiberglass cable connectors have advantages such as insulation, corrosion resistance (based on actual reports), ...

-

Application technical requirements of fiberglass threading device in complex working conditions

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring...

-

Installation, use, and daily maintenance of fiberglass cable connectors

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, con...

-

Manufacturing process of fiberglass threading device

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction too...