Application technical requirements of fiberglass threading device in complex working conditions

Publish Time:2026-01-23 18:21:21 Author:Xuanyao Views:135

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring strict requirements in material performance, structural design, operating standards, and environmental adaptability. The following is a system description of its key technical requirements:

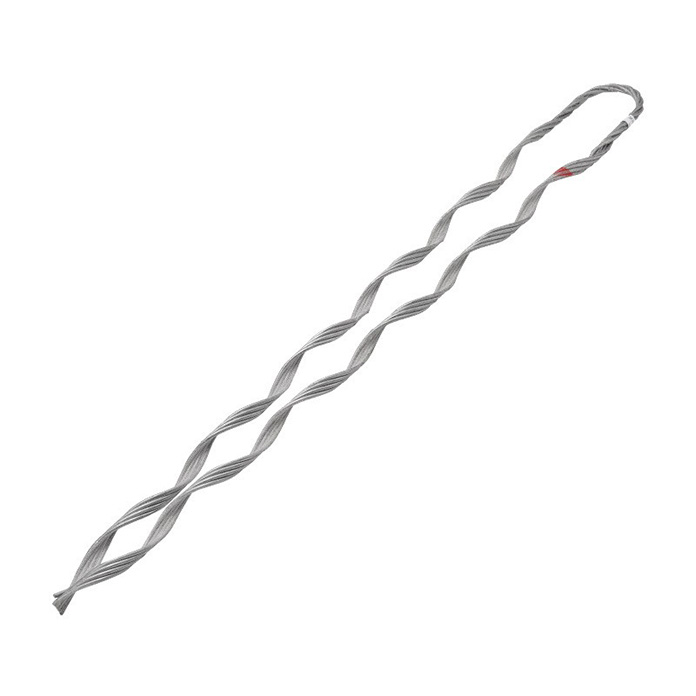

Firstly, in terms of mechanical performance, the threading device needs to have an excellent balance between tensile strength and bending toughness. Complex working conditions often involve pipeline systems with multiple bends, long distances, narrow spaces, or obstacles. The threading device needs to maintain structural integrity through repeated bending, twisting, and axial traction to avoid brittle fracture or long-term deformation. It is usually required that the longitudinal tensile strength is not less than 600 MPa, while having sufficient flexibility to pass through bends with small bending radii (generally not less than 10 times the diameter of the rod).

Secondly, surface quality and performance are crucial. When passing through concrete embedded pipes, metal sleeves, or old pipelines, there may be burrs, rust, or deposits on the inner wall, which can easily cause scratching and damage to the threading device. Therefore, the surface of the product should be smooth and dense. If necessary, wear-resistant (based on actual reports) coatings or high crosslinking resin systems can be applied to enhance wear resistance and prevent fiber exposure from causing a sudden drop in strength.

Thirdly, environmental adaptability is a core requirement under complex working conditions. The threading device may need to operate in high temperature, low temperature, humid, oily, or even weakly corrosive environments. For example, being in a high humidity state for a long time in underground utility tunnels, or being exposed to trace amounts of acidic and alkaline gases in chemical areas. At this point, the matrix resin should be selected from ethylene ester resin or modified epoxy system with good weather resistance, and UV resistance, moisture resistance (based on actual reports), and flame retardant additives should be added. It should be confirmed that the performance is stable within the range of -40 ℃ to+120 ℃, and the insulation resistance remains above 10 Ω· cm.

Fourthly, the demand for functional integration is becoming increasingly prominent. In pipelines with long distances or unclear paths, traditional threading devices are difficult to locate or determine whether they are connected. For this reason, flexible optical fibers, conductive cores, or RFID chips can be embedded in excellent applications to achieve real-time tracking, on/off detection, or path mapping during the threading process. This places high demands on the manufacturing process and requires the completion of composite packaging of functional components without damaging the main structure.

Fifthly, operational safety and human-machine collaboration cannot be ignored. Complex working conditions often require the cooperation of multiple people or mechanical assistance. The front end of the threading device should be equipped with standardized quick connect interfaces to facilitate the connection of guide heads, traction ropes, or electric threading equipment. At the same time, the overall weight needs to be controlled within a reasonable range, balancing rigidity and portability, reducing construction personnel fatigue, and lowering operational risks.

Afterwards, quality management throughout the entire lifecycle became a technical extension requirement. In key infrastructure such as nuclear power, rail transit, and data centers, threading devices are not only disposable tools, but also considered as a link in the engineering safety chain. Therefore, manufacturers need to provide batch traceability, aging performance data, and regular testing recommendations, while users should establish usage records and conduct mandatory retirement evaluations for threading devices that have experienced extreme working conditions.

In summary, the application of fiberglass threading tools in complex working conditions has evolved from a single material tool to a systematic solution that integrates performance stable composite materials, intelligent perception, and engineering adaptation. Its technical requirements cover multiple dimensions such as material technology, structural mechanics, electrical safety, and construction technology.

Related News

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex op...

-

Common usage issues of fiberglass threading device

Although fiberglass cable connectors have advantages such as insulation, corrosion resistance (based on actual reports), ...

-

Application technical requirements of fiberglass threading device in complex working conditions

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring...

-

Installation, use, and daily maintenance of fiberglass cable connectors

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, con...

-

Manufacturing process of fiberglass threading device

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction too...