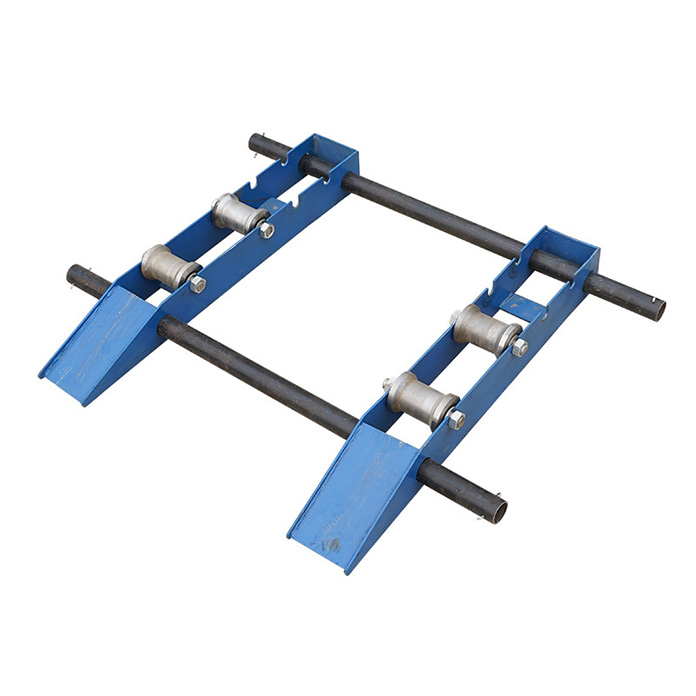

Cable laying rack

Description: Cable laying rack, also known as cable reel bracket or cable laying rack, is a one-to-one tool that is a flagship product in power construction, construction engineering, communication wiring, and various cable laying projects. It is mainly used to suppor...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

Cable laying rack, also known as cable reel bracket or cable laying rack, is a one-to-one tool that is a flagship product in power construction, construction engineering, communication wiring, and various cable laying projects. It is mainly used to support and release coiled linear materials such as cables, optical cables, steel wire ropes, etc., to ensure a smooth, effective, and secure laying process, and to effectively protect cables from damage.

1、 Core functions and importance

The core mission of cable laying racks is to solve the problem of manual handling and rotating release of heavy-duty cable reels. It supports the cable reel through a stable support structure, allowing it to rotate around the axis and achieve:

Effort saving effect: Avoiding manual lifting of heavy plates, a single person can control the smooth release of cables, greatly improving construction efficiency.

Protecting cables: Smooth rotation and unwinding can prevent cable twisting, knotting, or surface scratches, especially for optical cables and high-voltage cables with fine insulation layers.

Smooth operation: The stable support structure prevents the cable reel from rolling or tipping during operation, eliminating the risk of personal injury on the construction site.

Flexible adaptation: It can adapt to cable reels of different specifications, weights, and shaft hole sizes, with strong versatility.

2、 Main types and characteristics

According to structure, load-bearing capacity, and applicable scenarios, cable laying racks are mainly divided into the following categories:

1. Lightweight pay off rack (worm/screw type)

Structure: It usually consists of a triangular bracket, an adjustable screw top rod, and a load-bearing shaft.

Features: Use worm gear or threaded screw for height adjustment and tightening of the central hole of the cable reel. Compact structure and easy operation.

Applicable: Suitable for small cable reels, communication optical cables, temporary laying on construction sites, etc., with a load-bearing capacity generally below 1-2 tons.

2. Heavy duty hydraulic pay off rack

Structure: Adopting a sturdy steel frame structure, equipped with a hydraulic lifting system.

Features: The hydraulic pump drives the lifting and lowering of the top rod, making it easy to lift and lock heavy-duty cable reels ranging from several tons to tens of tons. Smooth lifting and lowering, strong locking force, and high safety.

Application: Installation of heavy-duty cables for large-scale power engineering, transmission and transformation projects, mines, ports, etc.

3. Double bar/gantry type pay off rack

Structure: Composed of two independent A-type brackets or a gantry frame, the support shaft spans between the two brackets.

Features: Good stability, support points distributed on both sides of the cable reel, uniform force distribution. Some models have adjustable support shaft heights and wide adaptability.

Applicable: Medium to large cable reels are commonly used standard configurations in the power industry.

4. Tracked/mechanically driven pay off rack

Structure: On the basis of the heavy-duty bracket, add motors, reducers, and track or rubber wheel drive devices.

Features: It can actively drive the cable reel to rotate forward and backward, realizing power unwinding or rewinding, controllable tension, and thoroughly freeing up manpower.

Applicable to large-scale specialized projects such as high-voltage cables and submarine cables that require high tension and stability for laying.

3、 Key structures and components

A typical cable laying rack typically includes:

Supporting frame: The main load-bearing structure is often welded with high-strength angle steel, channel steel, or rectangular pipes to ensure overall stability.

Lifting and lowering adjustment mechanism: screw, hydraulic cylinder or gear rack mechanism, used to accurately align and tighten the axis of the cable reel.

Bearing shaft/top cone: a component that is directly inserted into the center hole of a cable reel, usually with one end fixed and the other end extendable or detachable, making it easy to install the reel.

Braking device: manual or automatic brake, used to control the wire laying speed and prevent excessive rotation of the cable reel due to inertia.

Mobile parts: Bottom universal wheels and fixed casters, convenient for short distance movement of equipment on construction sites, and can be fixed with support feet after being in place.

4、 Selection Guide

Choosing a suitable cable laying rack requires comprehensive consideration of the following factors:

Cable reel parameters: large reel diameter, reel width, shaft hole diameter, and large weight.

Working environment: indoor, outdoor, flat or rugged terrain, determines the requirements for mobility and stability.

Wire laying requirements: Conventional gravity wire laying still requires power assistance and tension control.

Enron coefficient: The rated load of the selected equipment should be greater than the actual weight of the cable reel, leaving sufficient margin.

5、 Key points of operation and maintenance

Before operation: Check if all components are intact, if fasteners are loose, and if the brakes are responsive.

When loading: Use lifting equipment (such as a crane) to smoothly lift the cable reel onto the bracket, confirm that the center hole is aligned with the top shaft, and tighten it firmly.

In use: The wire laying speed should be uniform to avoid sudden pulling. Use the brake to smoothly control the speed.

Maintenance: Regular cleaning, adding lubricating oil to moving parts such as bearings, hydraulic cylinders, and threaded rods, checking for cracks or deformations in the structure, and confirming long-term excellent use.

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01