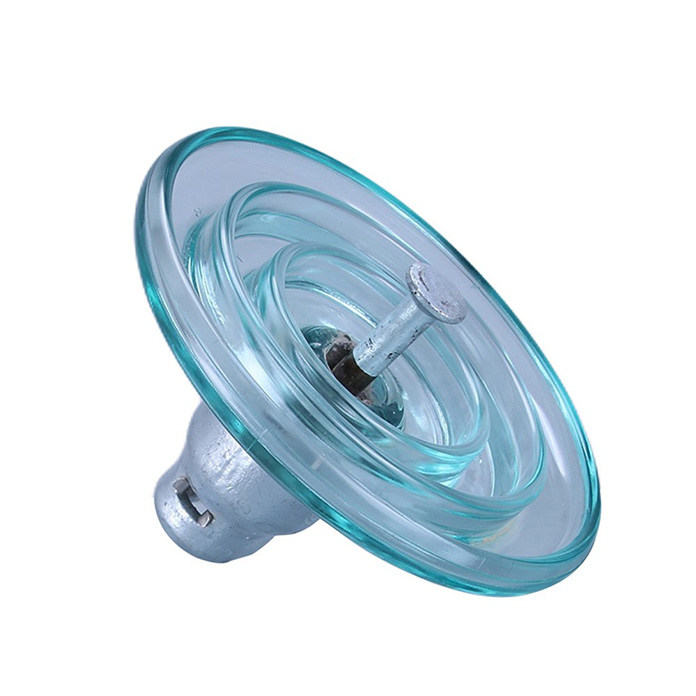

glass insulator

Description: Glass insulators are key components used to support wires and achieve electrical insulation in high-voltage and higher voltage transmission lines. It is made of specially tempered glass and holds an important position in the power industry due to its reli...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

Glass insulators are key components used to support wires and achieve electrical insulation in high-voltage and higher voltage transmission lines. It is made of specially tempered glass and holds an important position in the power industry due to its reliable "zero self explosion" characteristic.

1、 Core functions and importance

Glass insulators, as insulation barriers for overhead power lines, undertake a dual core mission:

Electrical insulation: Form excellent insulation isolation between the wire and the grounded part of the tower, withstand the working voltage and various overvoltages of the line, and prevent current leakage.

Mechanical support: bear the weight of the wire itself, wind load, ice load and other mechanical forces, and transmit them safely to the tower structure.

Its importance lies in the fact that the performance of insulators directly determines the insulation quality and operational safety of transmission lines, and is a good defense line for preventing pollution and lightning accidents in the power grid.

2、 Structure, Materials, and Manufacturing Process

1. Core structure

A complete glass insulator usually consists of three parts:

Tempered glass umbrella tray: The insulating body has undergone physical tempering treatment, resulting in a long-term pre stress on the surface.

Metal accessories: including iron caps and steel feet, usually made of cast iron or forged steel, connected to glass plates with cement adhesive.

Cement binder: usually high-strength Portland cement, which firmly binds glass, iron caps, and steel feet into a whole.

2. Core material: Tempered glass

Process: Heat borosilicate glass in a heating furnace above its softening point, and then perform appropriate and uniform cooling (air cooling).

Effect: The surface of the glass shrinks sharply, while the interior remains in an expanded state, resulting in strong long-term compressive stress on the surface and tensile stress on the interior.

Advantages: High mechanical strength (3-5 times that of ordinary annealed glass), good thermal stability, and endowed with "self explosion" characteristics.

3、 Core Features and Advantages

The effectiveness of glass insulators lies in their materials and structure:

1. "Zero value self explosion" characteristic (core advantage)

Principle: Once an insulator loses its insulation performance due to lightning strikes, aging, or manufacturing defects (referred to as "zero value" or "low value"), the internal tempered stress balance will be disrupted.

Performance: The entire glass umbrella tray will shatter in a short period of time, and the umbrella tray fragments (usually very small) will fall off.

Meaning: During ground or helicopter patrols, operation and maintenance personnel can accurately detect faulty insulators at a distance of 90% with the naked eye or telescope, without the need to climb towers and inspect each piece individually. This greatly improves inspection efficiency and defect detection rate.

2. High mechanical and electrical strength

Tempered glass itself has good strength, and its mechanical and electrical properties reach their peak in the early stages of operation, with minimal attenuation throughout its entire lifecycle.

Excellent resistance to arc and lightning strikes, it usually fractures as a whole after being damaged by lightning strikes, without producing inconspicuous local damage like ceramic insulators.

3. Excellent weather resistance and stability

The glass surface is an inert dense layer that does not adsorb moisture and has good hydrophobicity migration ability (moisture in pollutants is not easily formed into a continuous conductive film).

Good aging ability, stable electrical and mechanical performance after long-term operation.

The coefficient of temperature expansion is small, making it less susceptible to internal stress damage caused by cold and hot cycles.

4. High economic efficiency throughout the entire lifecycle

Although the initial procurement cost may be comparable to or slightly higher than that of porcelain insulators, their almost zero testing cost and high quality significantly reduce the full life operation and maintenance cost of the line.

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01