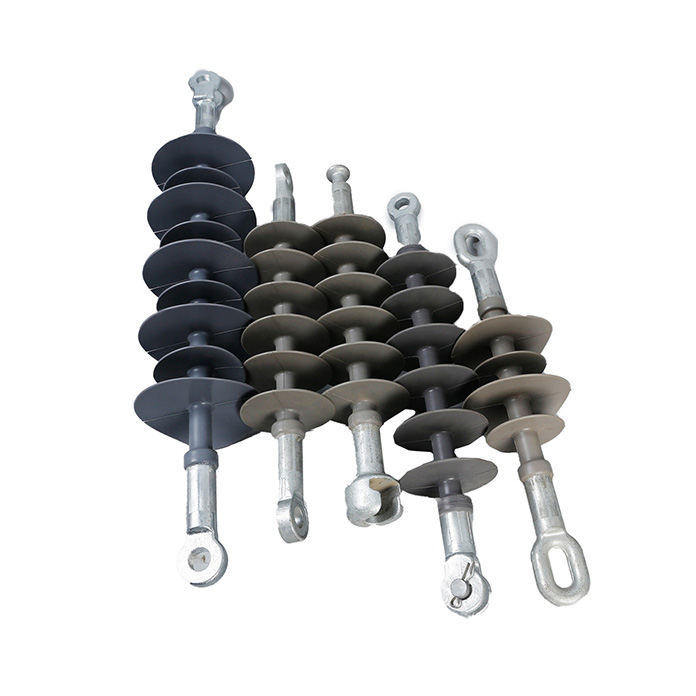

Silicone insulator

Description: Silicone rubber composite suspension insulator is the core insulation component of high-voltage and relatively high voltage overhead transmission lines, mainly used to suspend wires and achieve electrical insulation between wires and towers. It uses silic...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

Silicone rubber composite suspension insulator is the core insulation component of high-voltage and relatively high voltage overhead transmission lines, mainly used to suspend wires and achieve electrical insulation between wires and towers. It uses silicone rubber as the insulation umbrella skirt and epoxy glass fiber as the core rod, possessing excellent insulation performance, mechanical strength, and pollution flashover resistance, making it the mainstream equipment in modern power transmission engineering.

Core strengths

Silicone rubber umbrella skirt with outstanding stain and flash resistance

The umbrella skirt is made of high-temperature vulcanized silicone rubber, which has excellent hydrophobicity and self-cleaning properties. It can effectively prevent rainwater and dirt from adhering, greatly reducing the risk of flashover in humid and polluted environments. It is particularly suitable for complex climate areas such as heavily polluted areas and coastal areas.

High strength epoxy core rod with excellent mechanical properties

The tensile strength of the internal epoxy glass fiber core rod is 2-3 times that of traditional ceramic insulators, which can withstand the tension load of large-span lines and is not easily broken during long-term operation, improving the wind and ice resistance of the line.

Lightweight design, easy installation

The weight is only 1/3 to 1/2 of that of porcelain insulators, which is convenient for high-altitude transportation and installation, while reducing the load-bearing capacity of the tower and lowering the overall cost of the project.

Strong weather resistance and long lifespan

Silicone rubber and epoxy core rods have excellent resistance to ultraviolet radiation, ozone and corrosion, and can operate stably in extreme environments ranging from -40 ℃ to 100 ℃. The design life can reach more than 20 years.

Applicable scenarios

Power Engineering: Wire Suspension and Insulation for 10kV~1000kV High Voltage and Higher Voltage Transmission Lines

Municipal power grid: insulation of overhead lines in urban high-voltage distribution networks

Cross regional transmission: insulation protection for long-distance, heavily polluted high-voltage transmission lines

Rail Transit: Insulation Support for High Speed Rail and Light Rail Contact Network Systems

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01