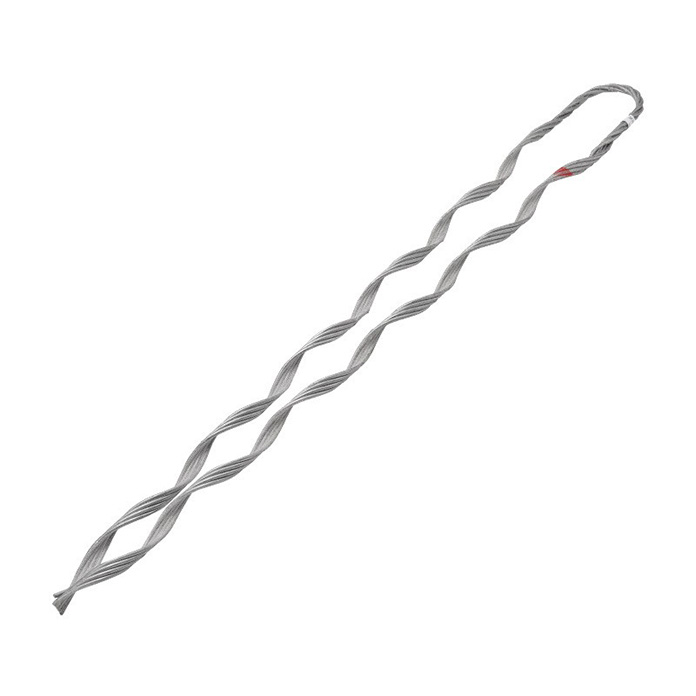

Pre twisted protective wire

Description: Pre twisted protective wire is a one-to-one protective fitting for overhead conductors and optical cables. It is mainly used to wrap around damaged sections or stress concentration points of conductors/optical cables, playing a role in reinforcing, anti v...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

Pre twisted protective wire is a one-to-one protective fitting for overhead conductors and optical cables. It is mainly used to wrap around damaged sections or stress concentration points of conductors/optical cables, playing a role in reinforcing, anti vibration, and protecting wires. It is an important protective component in high-voltage transmission and communication lines.

Core strengths

Spiral fitting structure, uniform force distribution

The spiral design of the pre twisted wire can tightly adhere to the surface of the wire/fiber optic cable, evenly distributing external forces over a longer contact section, avoiding stress concentration, and effectively preventing wire breakage or fiber optic cable damage.

Soft material, easy to install

Made of aluminum alloy material, it has good flexibility and can be installed by hand winding without the need for tools, greatly reducing construction time and lowering the risk of high-altitude operations.

Multiple protection functions

It can not only reinforce damaged wires, but also prevent wind-induced vibrations, and prevent secondary damage to wires caused by lightning strikes, foreign object friction, etc.

Excellent corrosion performance

Aluminum alloy material has good corrosion resistance and can operate stably for a long time in outdoor humid and salt spray environments, with a service life of over 20 years.

Applicable scenarios

Power Engineering: Reinforcement of Broken Strands and Anti Vibration Protection for High Voltage Transmission Line Conductors

Communication Engineering: Wear Protection and Stress Concentration Point Protection of Overhead Communication Optical Cables

Line repair: The speed of damaged wires/optical cables is suitable for reinforcement, and attentive service is provided

Strong wind areas: prevent wire micro wind vibration and extend wire life

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01