Manufacturing process of fiberglass threading device

Publish Time:2026-01-23 18:12:41 Author:Xuanyao Views:170

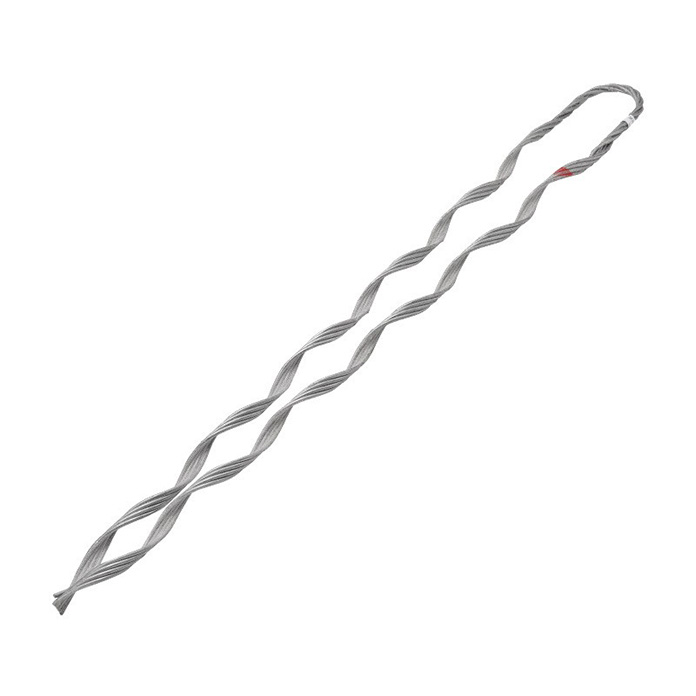

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction tool widely used in industries such as power, communication, and construction. It has the characteristics of good insulation, strength, corrosion resistance (based on actual reports), and good flexibility. The manufacturing process is mainly based on the molding technology of glass fiber reinforced thermosetting resin composite materials. The following are typical manufacturing processes and key technical points:

1、 Raw material preparation

Enhanced materials

Mainly using alkali free or medium alkali glass fiber yarn (E-glass or C-glass), continuous roving, untwisted roving or woven fabric can be used.

Matrix resin

Commonly used unsaturated polyester resin (UPR), epoxy resin, or vinyl ester resin, choose according to performance requirements.

Resin requires the addition of curing agents (such as methyl ethyl ketone peroxide MEKP), propellants (such as cobalt salts), release agents, flame retardants, and other functional additives.

2、 Main manufacturing process methods

1. Pultrusion - the most mainstream process

Suitable for mass production of threading rod bodies with constant cross-sectional area.

Process flow:

Fiberglass yarn frame → yarn guide plate → resin impregnation tank → preform mold → heating and curing mold → traction machine → cutting/winding

Advantages:

Good degree of automation and production efficiency

Excellent mechanical properties of the product (good longitudinal strength)

Smooth surface and stable size

Key control points:

Viscosity and impregnation uniformity of resin adhesive solution

Curing temperature curve (usually 120-180 ℃)

Matching traction speed and curing time

2. Filament Winding

Suitable for products that require high circumferential strength or special bending performance.

Wrap the impregnated fibers around the core mold at a specific angle, and then heat and cure them.

It can achieve local enhancement or variable diameter structure.

3. Hand lay up/compression molding (less commonly used for threading tool bodies)

Commonly used for the production of special-shaped end fittings such as elbows and guide heads.

Low cost but poor consistency, suitable for small batch customization.

3、 Post processing procedure

Cutting and trimming

Cut according to standard lengths (such as 50m, 100m) or customer requirements.

Polish the end to prevent burrs from damaging the cable.

surface treatment

Can spray wear-resistant (based on actual reports) coatings or add UV resistant layers to enhance outdoor service life.

performance testing

Bending strength, tensile strength, insulation resistance, voltage resistance testing, etc.

Compliant with industry standards such as DL/T 878, GB/T 1452, or enterprise standards.

Related News

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex op...

-

Common usage issues of fiberglass threading device

Although fiberglass cable connectors have advantages such as insulation, corrosion resistance (based on actual reports), ...

-

Application technical requirements of fiberglass threading device in complex working conditions

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring...

-

Installation, use, and daily maintenance of fiberglass cable connectors

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, con...

-

Manufacturing process of fiberglass threading device

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction too...